Product Details

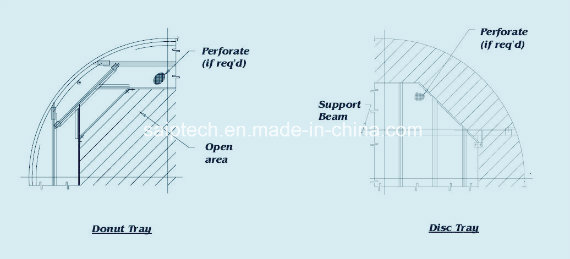

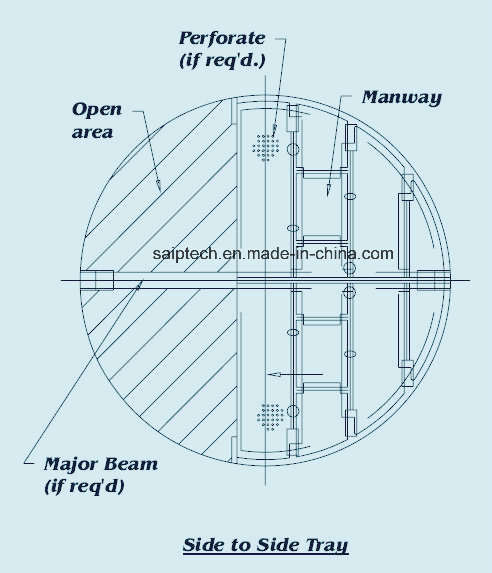

Saiptech's Side to Side Baffle and Disc and Donut Trays

For systems where extremely high capacity, fouling and pressure drop are major concerns, side to side baffle and disc and donut trays may be a suitable choice. For both of these tray types, liquid and vapor

contacting is accomplished by vapor passing through a curtain of liquid falling from one

tray to the next tray below. The tray decks are flat or inclined plates that block 40-60

percent of the cross sectional tower area. In addition to the sloped configuration for the tray decks, other design variations may include inlet or outlet weirs, uniform or partial perforated design. Typical side to side trays are depicted at right. Typical disc and donut trays are depicted below.

.

| Comparison of Common Conventional Tray |

| TRAY TYPE |

BUBBLE CAP |

DUALFLOW |

SIEVE |

VALVE |

| Capacity |

Moderate |

Very High |

High |

High to very high |

| Pressure Drop |

High |

Low to Moderate |

Low to Moderate |

Moderate.Older designs were somewhat higher.Recent designs same as sieve trays. |

| Efficiency |

Moderate (0.6 - 0.8) |

Lower compared to others (0.5 - 0.7) |

High (0.7 - 0.9) |

High (0.7 - 0.9) |

| Turndown |

Very high Can handle very Can handle very low liquid rates |

Low. Not suitable for suitable for varying loads |

Approx. 2:1. Unsuitable for Unsuitable for varying loads operation |

Approx. 3-5:1 Higher turndown Higher turndown designs can be provided on request. |

| Maintenance |

Relatively high |

Low |

Low |

Low to moderate |

| Fouling Tendency |

High. Tends to accummulate solid particles |

Extremely low. Best choice for Severe fouling |

Low |

Low to moderate |

| Main Application |

Very low flow conditions where leakage needs to be minimized |

Capacity revamps where efficiensy and turndown not critical high fouling and corrosive servies |

Most columns where trundown not important |

Most Columns services where turndown important |

| Cost |

High -approx 2~3 times that for sieve trays |

Low |

Low |

Marginally higher than sieve trays |

Company Profile

Company Profile