Product Details

Products Pictures

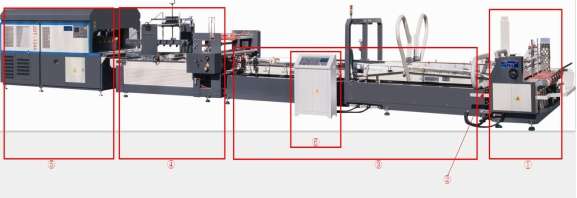

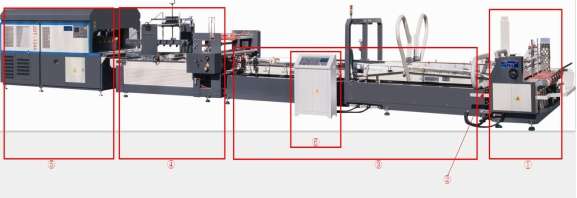

Main Structure

1. Auto Feeding 2. Auto Gluing 3. Auto Folding 4.Auto Stacking And Counting

5. Optional Bunlding Machine 6. Electrical Parts

Features

- Product yield rate can reached 98%.

- Machine parts manufactured by CNC lathe with high precision resulting in little vibration and long service life.

- 20mm thickness steel wall dealt with computer control aligning and 5mm thickness square foundation pipe makes the machine strong and solid. .

- The roller are made by 12mm thickness seamless steel pipe which are grinded, balance tested and chromed, ensuring roller vibration less than 0.03 mm.

- Four parts correction together with differential belt correction parts eliminates the fish tail problem effectively.

- Application Ranges: A C.B. AB flutes 3/5 layers corrugated board

- Glue even, fast-drying and easy to clean.

- Greatly reduce labor and material cost compared with stitcher.

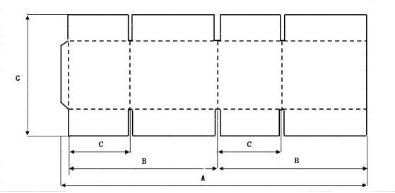

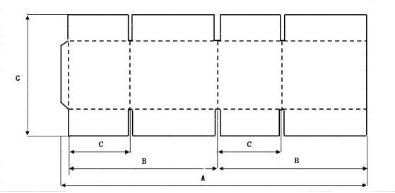

Carton Dimension

| Model |

|

JHX-2000 |

JHX-2800 |

A |

Max |

1900mm |

2600mm |

| Min |

700mm |

850mm |

B |

Max |

950mm |

1300mm |

| Min |

350mm |

425mm |

| C |

Min |

150mm |

150mm |

G |

Max |

900mm |

1200mm |

| Min |

250mm |

300mm |

Specifications

| Model |

JHX-2000

|

JHX-2800

|

| Max. Carton Size |

900×1900mm |

1200×2600mm |

| Min. Carton Size |

250×700mm |

300×850mm |

| Dimension (mm) |

13000×2400×2000 |

14000×3000×2000 |

| Installation Area |

4500×15000mm |

5000×16000mm |

| Total Power |

7.9Kw |

7.9Kw |

| Machine Weight |

4.8t |

5.0t |

| Power Supply |

Three Phase 380V |

Three Phase 380V |

| Glue Method |

25mm |

25mm |

| Glue Method |

Roller gluing |

Roller gluing |

Feeding Unit:

- Adopt high quality rubber vacuum belt, stocking and automatic input to ensure the efficiency of feeding.

- Special design makes the adjustment simply, quickly and precisely. The side regulation, paper feed baffle and belt are separately operated parts, which is easy to change the size of carton.

Gluing Unit

- The gluing width is 20-25 mm-gluing from bottom side.

- The glue box can be moved left or right according to the requirement of the corrugated board.

- The gluing amount can be adjusted.

- The glue box is made of stainless steel-big contain and easy for cleaning.

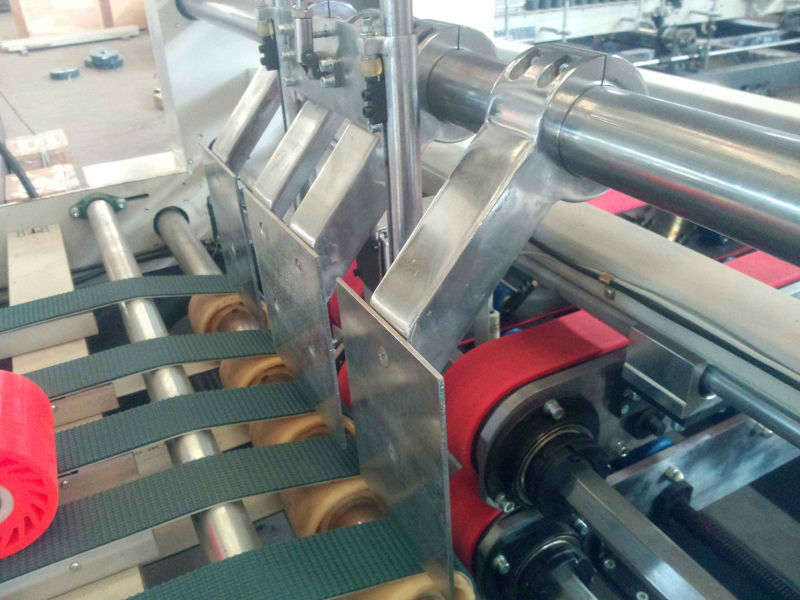

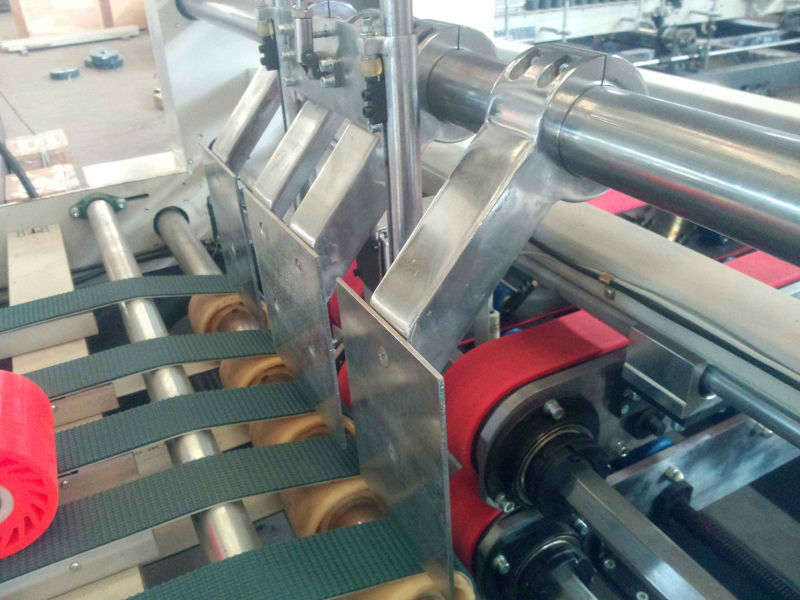

Folding Unit

- It uses high friction belt. The folding speed is controlled by frequency converter which can be controlled separately and synchronized with the main motor.

- Motor driven for order change adjustment-fast and convenient.

- Re-creasing roller, re-creasing knife, side roller and flapping plate can eliminate the fish tail effectively.

Stacking and Counting Unit

- The Flapping Plate can help to reduce the fish tail phenomenon.

- The pile number can be set at 10, 15, 20 and 25.

Electrical Parts

Scientific and reasonable mechanical structure, reliable quality electrical elements makes the machine free of trouble.

Installation Requirement

- Installation areas: Length × Width : 15000×4500mm

-

Training, installation and debugging:

- Seller in charge of installation, debugging and training in the buyer's factory. However the days used should be generally no more than seven days

- The buyer should try to help as much as they can while the supplier's engineer is debugging the machine by providing enough workers, powers, tools and some necessary documents or papers.

Electric Part:

Name

|

Brand

|

Model

|

| Frequency converter |

Shihlin |

3.7KW/2.2KW |

| Power |

Taiwan Mean Well |

S-150-24 |

| Contactor |

French Schneider |

LC1-D0910M5C

LC1-D0901M5C |

| Control button |

China |

|

| Control knob |

Fuji |

|

| Photoelectric switch |

Omron |

E3F3-D11 |

| Air switch |

Chint |

DZ47-60 |

| Touch screen |

Hitech |

190mm |

Main Mechanical Parts:

|

Name

|

Brand

|

Quantity

|

| 1 |

Feeding belt(A) |

Baiteli |

6 |

| 2 |

Receiving belt(C) |

Forbo-siegling |

15 |

| 3 |

Conveyor belt(B) |

Forbo-siegling |

9 |

| 4 |

High-pressure centrifugal fan |

Shanghai(Halon) |

1 |

| 5 |

Main Motor |

Simens(beide) |

1 |

| 6 |

Reducer |

Zhejiang |

6 |

|

Name

|

Quantity

|

| 1 |

Internal Hexagonal Spanner |

1 |

| 2 |

Screwdriver (plus) |

1 |

| 3 |

Screwdriver (minus) |

1 |

| 4 |

Pliers |

1 |

| 5 |

Monkey wrench |

1 |

| 6 |

Wrench |

3 |

Company Profile

Company Profile